Bifacial modules—you’ve likely heard quite a bit about them by now. They seem to be all anyone in the solar industry is talking about. What was once a more niche product, bifacial module technology is undeniably becoming one of the biggest trends and the hottest topics of conversation.

That’s why RP Construction Services, Inc.’s Director of Marketing Bri Bruce sat down with Tim Montague with Continental Energy Solutions to talk about optimal bifacial module performance on solar trackers, and the “power couple” that is the partnership between RPCS and solar tracker manufacturer and pioneer Array Technologies.

This interview was originally conducted for the Continental Energy Solutions podcast, produced by Tim Montague.

Tim Montague: First tell us about yourself and how you came to RPCS?

Bri Bruce: Sure. I am the Director of Marketing for RP Construction Services. I’ve been with the company for just shy of three years. Before joining RPCS I was working in sales and marketing in the tech world in Silicon Valley. Prior to that I spent most of my early career in the publishing industry, specifically in project management, PR, and digital media design.

Transitioning to the solar industry came very naturally and has been the best career move. I have not looked back and am very much a solar-lifer. But more than that I am beyond grateful to have found a home with the amazing team at RPCS. To top it off, we’re contributing to the clean energy future as well as driving economic growth and creating jobs—it’s a beautiful thing.

T: Give our listeners some background on RPCS and Array.

B: RPCS’s roots really begin at Array Technologies. Our founder and CEO, Eb Russell, used to lead the sales efforts at Array, and helped them deliver over 2GW and obtain 85% market share among trackers starting in 2009.

In 2015, we extended our partnership to begin offering our turnkey design-supply-build service to support developers and EPCs throughout the US.

We’re in a unique position in the market – Not many companies have been working with SAT since 2009. Not many companies have seen the lifecycles of other SAT companies like we’ve seen.

To date, we’ve completed hundreds of projects across 34 states and counting – we believe it’s our experience that makes us most valuable to our customers. That and dedicating ourselves to what we know to be the best tracker product for the industry leading manufacturer with over 30 years under their belt.

T: Tell us about your white paper on bifacial modules and the one module-in-portrait (1MIP) versus two module in portrait (2MIP) debate. Why is it relevant?

B: Bifacial modules are a hot topic right now. There’s been a lot of talk about their performance and what amount, exactly, of energy gain they can achieve. And I think the biggest point of contention when it comes to determining their productivity—aside from driving variables like albedo and geographic location—is what configuration (being 1MIP or 2MIP) is going to yield the highest energy gains.

The 1MIP versus 2MIP debate is counterintuitive: Twice the number of modules on the racking doesn’t equate to twice the energy gain. The output is only as good as the configuration.

It’s a relatively new technology, and because of this it’s difficult to determine definitively their added energy gain. This is the biggest unknown. And this is where factors like ground cover and location come in. But, what is known is that there is an added gain when using bifacial modules over monofacial modules—and that’s an average 3-10% gain.

Array Technologies conducted some extensive tests in partnership with PV Lighthouse and CFV Labs at their testing facility in Albuquerque, New Mexico. In my white paper, I set out with the goal to summarize the findings in a way that was digestible and highlight the benefits of the 1MIP configuration over the 2MIP configuration. I also provide a deeper look at why a 1MIP configuration on a single axis tracker, specifically the Array Technologies tracker, could yield the highest energy gain.

Developers, owners, and financers are seeking a more attractive bottom line—they’re looking for greater bankability, and this is something that can be obtained through maximized energy gain. Simply put, if you wanted to maximize gain, maximize the ROI of a system, while eliminating labor costs and installation complexity, maintenance, potential destruction during high wind events, you’d install the Array tracker with bifacial modules in 1MIP.

It’s important to note that for the sake of the white paper, we chose to exclude drivers like ground cover, albedo, and geographical location mostly because these factors can’t be controlled with the design of the system. However, we have published an additional in-depth additional article that covers these drivers and their role on performance: https://www.rpcs.com/bifacial-module-performance-solar-trackers/

T: Many SAT makers are developing or have developed 2 MIP trackers…your report suggests that this is not the most productive tracker arrangement for bifacial modules…so what are the biggest advantages to using 1MIP?

B: We don’t feel there are any benefits to 2MIP. We’ve abandoned the idea because it just doesn’t really make sense. We’re very strong advocates against 2MIP on trackers – fixed tilt is a different story, but our focus is on trackers.

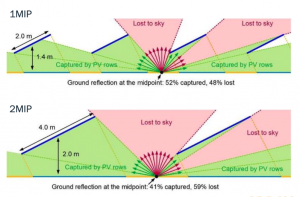

There are a few important visuals that help compare the two configurations and illustrate the biggest advantages to 1MIP. One was built by one of our engineers and the other is from Array and is based on their testing.

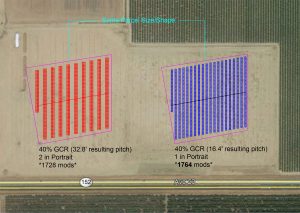

The first image, Figure 1, shows two identical parcels of land of exactly the same size and shape, one is using 2MIP (left) and the other is using 1MIP (right). Both sites have a ground coverage ratio, or GCR, of 40%. GCR refers to the relation of module area to the total land area occupied by a solar array.

As the figure illustrates, the 2MIP configuration has half the amount of rows as the 1MIP configuration, but the 1MIP set up actually has more modules.

Because the arrays need to maintain a certain GCR, so as to properly track the sun and not create row-to-row shading, the 2MIP rows need to be spaced farther apart. Added height, without added row spacing or pitch, increases ground shading which in turn increases ground coverage ratio (GCR) and lets less solar irradiance reach the ground to be reflected.

FIGURE 2

Figure 2, by Array Technologies, shows the amount of solar irradiance that is reflected off the ground with 1MIP (top) and 2MIP (bottom).

A 2MIP configuration requires the modules to be mounted farther from the ground. To match the tracker aspect ratio ( the row height in relation to row width or row spacing) of the shortest 1MIP configuration, a 2MIP tracker would need to be built with the torque tube at nearly 3 meters high. The increased height of the stacked modules changes the center of rotation on the torque tube to give the bottom edge of the module proper clearance as it tracks.

Having modules higher off the ground decreases gain due to the amount of reflected solar energy lost to the sky. Added height, without added row spacing, also increases ground shading—and can potentially cause row-to-row shading when the sun is at a low angle in mornings and evenings—which in turn increases GCR, letting less solar irradiance reach the ground to be reflected.

As visualized in the diagrams, there is an 11% increase in light capture with the lower torque tube height of the 1MIP configuration, which does not allow as much reflected light to escape.

Height increases impact installation costs negatively due to deeper foundations, more hardware and structural support to provide stability, and additional installation labor costs with above head-height modules.

T: What about single-sided modules? How would production benefit from bifacial? What about installation costs?

B: Bifacial modules are comparable in price to monofacial mods. I would surmise that as technology improves and becomes more efficient that any difference in price would be a wash.

The Array system deploys by default a 1MIP configuration – this is the basis for their industry success. So, you’re starting, baseline, with that same reliability while adding a 3 to 10% boost in going with bifacial mods. Installation of bifacial modules would be no different than installation of monofacial modules.

Going with a 2MIP configuration would be doing the project a disservice threefold: from a cost perspective, from an installation perspective, and from production standpoint.

I want to bring to light the two major structural pitfalls of the 2MIP configuration: potential failures during high wind events due to greater drag and increased array height to account for change in center of rotation.

With 2MIP, you’re essentially creating a bigger “sail” to catch the wind. There’s a higher failure probability in the event of an extreme wind event.

Labor costs and installation complexity also increase with 2MIP. The system needs more metal to support more material on the racking, and longer piles need to be driven to support a system that is higher off the ground— essentially, you’re adding more failure points to the system as a whole.

You’ll hear some naysayers of 1MIP talk about how the center torque tube shades the module. Tests are conclusive in determining that this was nominal—a .02% loss. What’s more, to mitigate this, Array has developed a special “Hi-Rise” clamp that brings the module farther off the center torque tube to let more reflected solar irradiation hit the modules’ backside. But this clamp isn’t necessary in mounting bifacial modules, the standard clamp is compatible.

T: What are some other aspects of Array that make it such a sought-after brand? In my experience, upwards of 80% of developers are specifying Array trackers on their community solar projects in Illinois. If you’re a developer or installer, what sets Array and RPCS apart from other SAT products?

B: Those stats are typical for what we’re seeing across the country—more developers are choosing the Array tracker. RPCS is winning roughly 75% of projects 5MW to 50MW range (that’s not to say we aren’t building projects in the 200MW range, though). We’ve also done a large number of projects in Illinois; by the end of this year we’re slated to have completed upwards of 60 projects.

To speak to the RPCS/Array relationship, we’re like a power couple.

RPCS provides the utility market with a turnkey solution for our customers—everything from engineering to supply and Safe Haber to mech install and commissioning. We’re not just a preferred installer. We’re entirely self-performant. That’s to say we own the contract, we use company-owned equipment, we have a crew of direct hires that is mobile and can be deployed anywhere in the U.S.

As an installer, we have a laser-focused, streamlined installation process to allow for repeatability, and we believe the Array tracker is the best deployable option out there. This contributes to our scheduling simplicity and our high degree of project productivity.

It has the fewest components—and thus the fewest failure points. The Array product is robust, known for its dependability. With its built-in mind mitigation system, you just won’t see wind failures—in fact, they’ve withstood hurricanes virtually unscathed. It’s designed to do what it’s supposed to with zero scheduled maintenance. It’s a 30-plus-year asset so you’re seeing both short- and long-term ROI. It’s simply the best product on the market.

T: Trackers have begun to dominate ground mount solar because they offer 10-20% greater productivity . . . is the 1MIP here to stay? What about bifacial modules?

B: I absolutely believe that 1MIP is here to stay, especially when it comes to trackers. Depending on the location of the array—both geographically and east-west positioning—you’re seeing gains up to 25% over fixed-tilt. Add bifacial modules and you’re getting an added 3-10% boost on top of that. And an optimal configuration of 1MIP will maximize gains even more—especially when deploying Array’s trackers.

T: When RPCS looks into their crystal ball, what do you see in 5, 10, and 20 years? How else is PV technology evolving that our listeners want to know?

B: Technology is constantly evolving, it’s improving. We’re bidding projects with a 450W module—we wouldn’t have seen that coming even five years ago. No one can really know what the market will look like in 5 years, let alone 20; it’s called the “solar coaster” for a reason.

Our hats are off to Array for consistently innovating. They’ve most recently created a more universal center structure to make installs faster, and have developed module clamps to accommodate thin film modules by First Solar—and, case in point, the “Hi-Rise” clamp is a new innovation specifically designed for bifacial modules. We’re proud to be Array’s trusted partner.

Over the years RPCS is becoming better and better at what we do. We’re able to take on more projects and bigger projects, all while furthering our expertise and focus at installing Array trackers. We’re outpacing the industry in growth. Aside from our stellar team, we owe most of our success to our industry experience and our narrow focus on working with one product.

We do one thing exceedingly well and we’ve committed ourselves to installing the system the right way so that it performs for its rated 30-plus years. We’ve made it our mission to build the best, and just as Array’s product is built on quality and reliability, our own values mirror that in how we serve our customers.

To download the white paper, “Bifacial Modules + Solar Trackers: 1MIP vs. 2MIP on Single Axis Solar Trackers,” visit https://www.rpcs.com/bifacial-modules-1mip-vs-2mip/.

To listen to the podcast where this interview first aired, visit https://youtu.be/kgoPdBRXVIk

RP Construction Services, Inc. (RPCS) designs, supplies, and builds utility-scale ground mount solar projects. With more than 500 completed projects throughout the United States, RPCS provides full turnkey service and support, including site layout optimization, ancillary engineering services, tracker supply, foundation post procurement, and complete mechanical installation. As a trusted partner of leading solar tracker manufacturer Array Technologies, RPCS’s history, experience, and product knowledge provides customers with a trusted choice for seamless portfolio execution.